Repair

Repair Common Sprinkler System Problems – Explore DIY Resources or Find a Professional.

- High water pressure

- Low or tilted heads

- Blocked heads

- Mixed or mismatched heads

- Clogged or wrong nozzles

- Low water pressure

High Water Pressure

Improper pressure can cause serious problems in the sprinkler system, and will result in inefficient watering. High pressure causes smaller droplets or mists to be sprayed out of the sprinkler head. This results in water being blown down the street or evaporating into the air. High pressure can cause sprinkler heads to wear out more quickly, and you’ll have to replace them more frequently.

You can test water pressure directly at the sprinkler head by adapting a screw on pressure gauge. Unscrew the sprinkler head, screw on a pressure gauge, run the zone

To reduce the pressure on the affected zone(s), you can install a pressure regulator on the valve that feeds a particular zone. Pressure regulators can be purchased online or your local hardware store that carries irrigation equipment.

WaterSense labeled spray sprinkler bodies are designed with pressure regulation. This can help decrease the outdoor water waste associated with irrigation systems that receive water under higher pressure.

Low or Tilted Heads

To fix low or tilted heads, use a shovel to dig around the head, remove the sod and carefully clear the vicinity of dirt. Next lift and straighten the head, packing soil under and around it until it is even with the ground and can easily clear the grass when it pops up. If lifting is not possible, replace the riser with a longer one. Adjust the nozzle to face the correct direction.

Mixed or Mismatched Heads

Mixed heads, otherwise known as mixed zones, occur when a single irrigation zone has more than one type of sprinkler head or more than one manufacturer’s products. This is a common design flaw on many sprinkler systems, and usually means there are some rotor heads and some spray heads on the same zone. This creates problems when you program the controller.

Spray heads are designed to emit about 50% more water than rotor heads in the same time period, some areas of the mixed zone will either receive too much water or not enough water. Consider a mixed zone with 4 spray heads on one side and 4 rotor heads on the other. If you program the schedule to water just the right amount for the spray heads, the rotor heads won’t have enough time to give their area of grass as much water as it needs. Alternatively, if the schedule is programmed for rotor heads, the area of grass covered by the spray heads will be getting too much water. Either way mismatched heads can lead to dry, brown spots of grass, soggy lawn and wasted water. Visit Retrofit section.

Clogged Nozzle

First, make sure the system is off. Lift the stem out of the head by the nozzle, unscrew the nozzle and take it off of the spray head. Hold onto the stem, or clamp it to prevent it from dropping back into the body. Take the filter out of the stem and wash out any debris in the filter or nozzle. Put the clean filter back into the stem and screw the nozzle back on to the stem. Finally, adjust the spray pattern to ensure that water is spraying on the intended coverage area.

Low Water Pressure

Low water pressure prevents heads from popping up all the way resulting in poor coverage and dry, brown spots of grass.

To measure water pressure, you will need a water pressure gauge. Make sure no water is being used in the house or yard. Attach the water gauge to an outside hose bib. Turn on the water. Water pressure should be between 30 and 80 psi. If you have an older system avoid reaching 80 psi.

To adjust water pressure for the whole house, find the water pressure regulator located on the main line. If needed, you can add a water pressure regulator on the sprinkler system. Drip irrigation is less effective if the water pressure is too high. Low pressure may be an indication that something else is wrong with the system, such as a broken head, leaking pipe, or malfunctioning valve. If there are no leaks or breaks, you may want to consider retrofitting with sprinkler heads designed for low water pressure.

- Overwatering

- Compacted soil

- Broken head or pipe

Overwatering

Runtimes that are too long or too frequent, or irrigating after rain, can keep water from infiltrating into the soil. Schedule irrigation based on the seasonal water needs. Consider replacing a clock-based controller with a weather-based or soil moisture-based irrigation controller.

Cycle and Soak – The most efficient way to water your lawn is to use the “cycle and soak” method. This method breaks up your watering time into smaller cycles, allowing the water to soak into the soil. If an area is watered too fast for too long, many soils can’t absorb it, resulting in runoff. Avoid watering for short periods in both the morning and the evening. The water doesn’t soak deeply into the soil, leading to shallow roots and unhealthy grass. The cycle and soak watering method not only saves water, but also improves your lawn’s health. Moisture deep in the soil promotes deeper roots, which contributes to a thicker, healthier, greener lawn.

Broken Head or Pipe

Inspect the sprinklers for a broken head or nozzle. If all heads and nozzles are working then it may be a broken pipe. Visit the section on Leak Detection.

- High water pressure

- Wrong spray heads or nozzle

- Sprinkler head spacing, head-to-head spacing, or not enough heads to cover the area.

- Low, tilted, or blocked heads

- Low water pressure

- Water lost to evaporation

High Water Pressure

Improper pressure can cause serious problems in the sprinkler system, and will result in inefficient watering. High pressure causes smaller droplets or mists to be sprayed out of the sprinkler head. This results in water being blown down the street or evaporating into the air. High pressure can cause sprinkler heads to wear out more quickly, and you’ll have to replace them more frequently.

You can test water pressure directly at the sprinkler head by adapting a screw on pressure gauge. Unscrew the sprinkler head, screw on a pressure gauge, run the zone

To reduce the pressure on the affected zone(s), you can install a pressure regulator on the valve that feeds a particular zone. Pressure regulators can be purchased online or your local hardware store that carries irrigation equipment.

WaterSense labeled spray sprinkler bodies are designed with pressure regulation. This can help decrease the outdoor water waste associated with irrigation systems that receive water under higher pressure.

Wrong spray heads or nozzle

Common types of sprinkler heads include fixed spray heads, rotary nozzles, rotor heads, manual sprinklers. Spray heads, with a shorter throw distance, are designed to cover smaller areas of grass like a front yard or side strip. Rotor heads, on the other hand, have much longer throw distances and are meant to cover larger areas of grass like a back yard or a ball field.

If fixed spray heads are used on larger areas of grass, the area may not be fully covered. That would result in dry, brown spots of grass. Alternatively, if rotor heads are used on a small patch of grass, the result is overspray and water waste. Both instances are examples of an inappropriate head type being used on a zone.

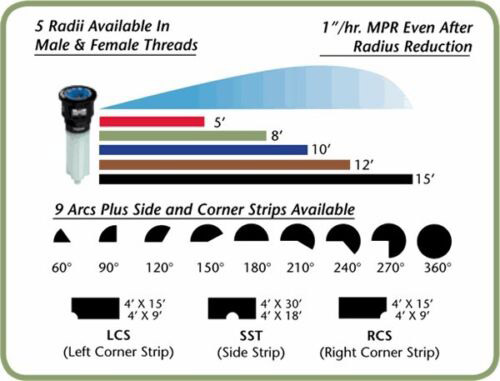

Nozzles vary by radius and arcs. Incorrect nozzling can cause poor distribution of water

To fix the issue, replace the inappropriate head or nozzle type with the correct one. If the spray head is being used on a larger zone, you may be able to replace the nozzle with a high-efficiency rotary nozzle. Be sure to adjust the run time on that zone as high efficiency rotary nozzles emit one-third the amount of water that a spray nozzle does in the same period of time.

Each zone should have the same type of heads and the same manufacturer.

Sprinkler head spacing, head-to-head spacing, or not enough heads to cover the area.

A sprinkler system design should incorporate “head- to-head spacing.” This means the spray of one head should reach the closest heads around it to ensure an even distribution of water. Without head-to-head spacing, a zone may have uneven distribution and some grass on the zone won’t get as much water as it needs, resulting in dry, brown spots of grass. Poor head spacing may be fixed with appropriate nozzle sizes and shapes. However, it may require redesigning the zones with the problem.

Low or Tilted Heads

To fix low or tilted heads, use a shovel to dig around the head, remove the sod and carefully clear the vicinity of dirt. Next lift and straighten the head, packing soil under and around it until it is even with the ground and can easily clear the grass when it pops up. If lifting is not possible, replace the riser with a longer one. Adjust the nozzle to face the correct direction.

Water Lost to Evaporation

Avoid watering in the heat of the day. Water before 10:00 am or after 6:00 pm

Overwatering

Runtimes that are too long or too frequent, or irrigating after rain, can keep water from infiltrating into the soil. Some people have heard the myth that nighttime watering is the cause of fungus but that is not a factor in our region. Schedule irrigation based on the seasonal water needs. Consider replacing a clock-based controller with a weather-based or soil moisture-based irrigation controller.

Compacted Soil

If the soil is compacted aeration can improve penetration of the water, increase root depth, and reduce the growth of moss and fungus.

- Clogged heads or nozzles

- Low water pressure

- Broken or leaking control valve

- Low or tilted heads

Clogged Heads or Nozzles

First, make sure the system is off. Lift the stem out of the head by the nozzle, unscrew the nozzle and take it off of the spray head. Hold onto the stem, or clamp it to prevent it from dropping back into the body. Take the filter out of the stem and wash out any debris in the filter or nozzle. Put the clean filter back into the stem and screw the nozzle back on to the stem. Finally, adjust the spray pattern to ensure that water is spraying on the intended coverage area.

Low Water Pressure

Low water pressure prevents heads from popping up all the way resulting in poor coverage and dry, brown spots of grass.

To measure water pressure, you will need a water pressure gauge. Make sure no water is being used in the house or yard. Attach the water gauge to an outside hose bib. Turn on the water. Water pressure should be between 30 and 80 psi. If you have an older system avoid reaching 80 psi.

To adjust water pressure for the whole house, find the water pressure regulator located on the main line. If needed, you can add a water pressure regulator on the sprinkler system. Drip irrigation is less effective if the water pressure is too high.

Fixing low pressure can be challenging. Low pressure may be an indication that something else is wrong with the system, such as a broken head, leaking pipe, or malfunctioning valve. If there are no leaks or breaks, you may want to consider retrofitting with sprinkler heads designed for low water pressure.

Broken or Leaking Control Valve

The sprinkler system controller communicates with each control valve, telling it when to open and provide water to the zone it controls. If the valve is broken it is unable to distribute water to its zone or only distributes a small amount of water to the zone, leaving the sprinkler heads unable to pop up all the way and emit the amount of water the grass needs. A broken valve will need to be replaced.

When sprinklers are leaking after the irrigation controller has been turned off, try using the bleed screw to flush the valve first. If flushing doesn’t work there may be debris in the diaphragm.

Water may leak through the zone valve. A check valve in the sprinkler will not fix this leak. There may be debris obstructing the valves diaphragm. If the zone valve for a particular zone is diagnosed as the problem then the solution is:

- disassemble the valve

- rinse all the parts with clean water

- re-assemble the valve.

You may need to replace the diaphragm assembly if there is visible damage or if continues to leak. Replacement diaphragm kits for brand name products can purchased at most retailer locations.

Low or Tilted Heads

To fix low or tilted heads, use a shovel to dig around the head, remove the sod and carefully clear the vicinity of dirt. Next lift and straighten the head, packing soil under and around it until it is even with the ground and can easily clear the grass when it pops up. If lifting is not possible, replace the riser with a longer one. Adjust the nozzle to face the correct direction.

- Clogged heads or nozzles

- High water pressure

Clogged Heads or Nozzles

First, make sure the system is off. Lift the stem out of the head by the nozzle, unscrew the nozzle and take it off of the spray head. Hold onto the stem, or clamp it to prevent it from dropping back into the body. Take the filter out of the stem and wash out any debris in the filter or nozzle. Put the clean filter back into the stem and screw the nozzle back on to the stem. Finally, adjust the spray pattern to ensure that water is spraying on the intended coverage area.

High Water Pressure

Improper pressure can cause serious problems in the sprinkler system, and will result in inefficient watering. High pressure causes smaller droplets or mists to be sprayed out of the sprinkler head. This results in water being blown down the street or evaporating into the air. High pressure can cause sprinkler heads to wear out more quickly, and you’ll have to replace them more frequently.

You can test water pressure directly at the sprinkler head by adapting a screw on pressure gauge. Unscrew the sprinkler head, screw on a pressure gauge, run the zone

To reduce the pressure on the affected zone(s), you can install a pressure regulator on the valve that feeds a particular zone. Pressure regulators can be purchased online or your local hardware store that carries irrigation equipment.

WaterSense labeled spray sprinkler bodies are designed with pressure regulation. This can help decrease the outdoor water waste associated with irrigation systems that receive water under higher pressure.

- Wrong head or nozzle type

- Tilted or misdirected heads

- High pressure

Wrong head or nozzle type

Common types of sprinkler heads include fixed spray heads, rotary nozzles, rotor heads, manual sprinklers. Spray heads, with a shorter throw distance, are designed to cover smaller areas of grass like a front yard or side strip. Rotor heads, on the other hand, have much longer throw distances and are meant to cover larger areas of grass like a back yard or a ball field.

If fixed spray heads are used on larger areas of grass, the area may not be fully covered. That would result in dry, brown spots of grass. Alternatively, if rotor heads are used on a small patch of grass, the result is overspray and water waste. Both instances are examples of an inappropriate head type being used on a zone.

Nozzles vary by radius and arcs. Incorrect nozzling can cause poor distribution of water

To fix the issue, replace the inappropriate head or nozzle type with the correct one. If the spray head is being used on a larger zone, you may be able to replace the nozzle with a high-efficiency rotary nozzle. Be sure to adjust the run time on that zone as high efficiency rotary nozzles emit one-third the amount of water that a spray nozzle does in the same period of time.

Each zone should have the same type of heads and the same manufacturer.

Tilted and Misdirected Heads

To fix tilted heads or misdirected heads, use a shovel to dig around the head, remove the sod and carefully clear the vicinity of dirt. Next lift and straighten the head, packing soil under and around it until it is even with the ground and can easily clear the grass when it pops up. If lifting is not possible, replace the riser with a longer one. Adjust the nozzle to face the correct direction.

High Water Pressure

Improper pressure can cause serious problems in the sprinkler system, and will result in inefficient watering. High pressure causes smaller droplets or mists to be sprayed out of the sprinkler head. This results in water being blown down the street or evaporating into the air. High pressure can cause sprinkler heads to wear out more quickly, and you’ll have to replace them more frequently.

You can test water pressure directly at the sprinkler head by adapting a screw on pressure gauge. Unscrew the sprinkler head, screw on a pressure gauge, run the zone

To reduce the pressure on the affected zone(s), you can install a pressure regulator on the valve that feeds a particular zone. Pressure regulators can be purchased online or your local hardware store that carries irrigation equipment.

WaterSense labeled spray sprinkler bodies are designed with pressure regulation. This can help decrease the outdoor water waste associated with irrigation systems that receive water under higher pressure.

- Low head drainage – install check valve

- Debris in valve diaphragm

- Sprinkler body cap issues

Low Head Drainage

The most common reason why a sprinkler will leak water when the system is off is called “Low Head Drainage.” Low head drainage occurs when the lowest head on a zone allows water to drain from the lateral piping, out of the sprinkler. If it is low head drainage, residual water will stop flowing after all the water has left the pipe.

The solution is to install check valves on sprinklers at the lowest points in a zone. Check valves are a device inside a sprinkler head that prevents water from leaking out after the zone turns off. This keeps water in the underground pipes and prevents gravity from pushing the leftover water out of the lowest heads in a zone. When purchasing a new head, be sure to look for models that have built-in check valves.

Debris in Valve Diaphragm

Water may leak through the zone valve. A check valve in the sprinkler will not fix this leak. There may be debris obstructing the valves diaphragm. If the zone valve for a particular zone is diagnosed as the problem then the solution is:

- disassemble the valve

- rinse all the parts with clean water

- re-assemble the valve.

You may need to replace the diaphragm assembly if there is visible damage.

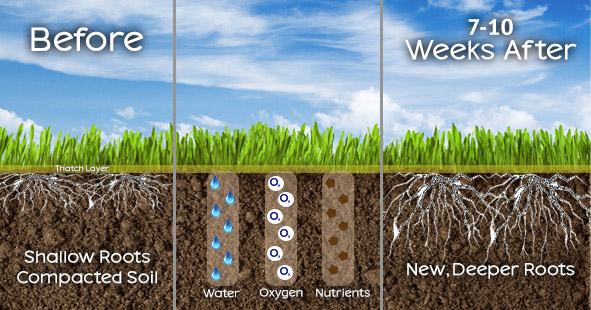

Cycle and Soak

The best way to water your lawn is to use the “cycle and soak” method. This method breaks up your watering time into smaller cycles, allowing the water to soak into the soil. If an area is watered too fast for too long, many soils can’t absorb it, resulting in runoff. Avoid watering for short periods in both the morning and the evening. The water doesn’t soak deeply into the soil, leading to shallow roots and unhealthy grass. The cycle and soak watering method not only saves water, but also improves your lawn’s health. Moisture deep in the soil promotes deeper roots, which contributes to a thicker, healthier, greener lawn.

Increase Root Zone Depth – Root Zone Depth Importance

Grass root zone depth equals water storage. Check root depth using a shovel. Dig deep enough to see the bottom of the root zone and measure the depth. Root depth may vary in different parts of your yard so you may want to perform the shovel test in multiple locations. A shallow root zone is under 3 to 4 inches deep.

You can promote a deeper root zone by watering for longer periods of time but less often. The idea is to soak the soil and allow it to dry out, so the grass feels stressed and sends roots deeper searching for water. A hardened or toughened lawn, attained through less frequent, deep irrigation, often withstands minor droughts, and has fewer disease problems. However, do not allow the grass to become overly drought-stressed between waterings. This can weaken the grass and make it more susceptible to damage from insects, diseases, and weeds.

- Misplaced drip lines

- Clogged drip lines

- High water pressure

- Low water pressure

Misplaced Drip Lines

Micro irrigation drippers should be placed near the root zone of each plant. Move drip line off bare soil and into the plant’s root zone.

Clogged Drip Lines

The treatment to solve a clogging issue in drip systems generally depends on the cause of the clogging. Clogging may come from 1) Particulates like sand, silt, or minerals, 2) Biological clogging from algae, or bacterial slimes and 3) Chemical precipitates such as calcium carbonate(lime) and iron. Check out the Nerds section on Drip Irrigation.

High Water Pressure

Improper pressure can cause serious problems in the sprinkler system, and will result in inefficient watering. High pressure causes smaller droplets or mists to be sprayed out of the sprinkler head. This results in water being blown down the street or evaporating into the air. High pressure can cause sprinkler heads to wear out more quickly, and you’ll have to replace them more frequently.

You can test water pressure directly at the sprinkler head by adapting a screw on pressure gauge. Unscrew the sprinkler head, screw on a pressure gauge, run the zone

To reduce the pressure on the affected zone(s), you can install a pressure regulator on the valve that feeds a particular zone. Pressure regulators can be purchased online or your local hardware store that carries irrigation equipment.

WaterSense labeled spray sprinkler bodies are designed with pressure regulation. This can help decrease the outdoor water waste associated with irrigation systems that receive water under higher pressure.

Low Water Pressure

Low water pressure can reduce the amount of water being delivered through the drip system emitters.

To measure water pressure, you will need a water pressure gauge. Make sure no water is being used in the house or yard. Attach the water gauge to an outside hose bib. Turn on the water. Water pressure should be between 30 and 80 psi. If you have an older system avoid reaching 80 psi.

To adjust water pressure for the whole house, find the water pressure regulator located on the main line. If needed, you can add a water pressure regulator on the sprinkler system. Drip irrigation is less effective if the water pressure is too high. Low pressure may be an indication that something else is wrong with the system, such as a broken head, leaking pipe, or malfunctioning valve. If there are no leaks or breaks, you may want to consider retrofitting with emitters designed for low water pressure.